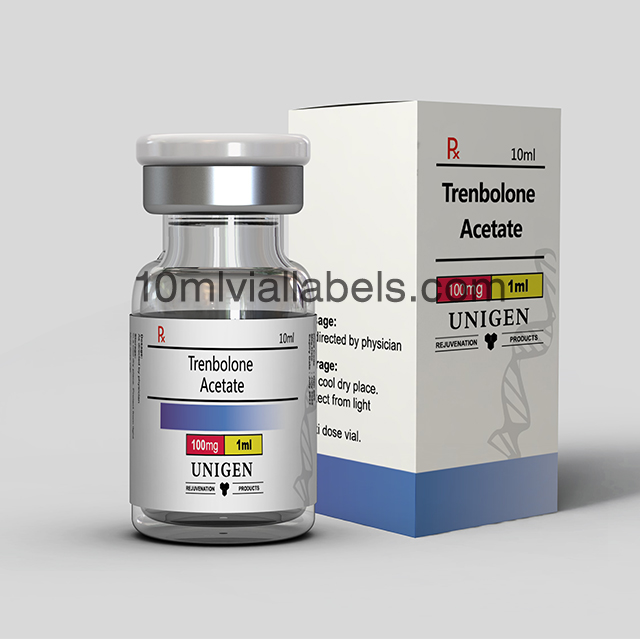

FREE Design on vial box

What sets this paper box apart is the incredible level of personalization it offers. Whether you’re a small boutique brand or a large corporation, this packaging can be tailored to suit your unique style and requirements. Our dedicated design team will work closely with you to understand your brand’s essence, helping you create packaging that resonates with your target audience and reflects your values.

And guess what? This exceptional design service comes absolutely free of charge! We believe that every brand, regardless of its size, deserves to have packaging that aligns with its vision. So, take this opportunity to turn your packaging dreams into reality, without worrying about additional costs. This paper box’s versatility knows no bounds. Ideal for cosmetics, jewelry, electronics, or any other high-end products, it exudes elegance and sophistication, making it the perfect complement to your premium merchandise. Rest assured that your products will make a grand entrance, leaving a lasting impression on your customers.

In conclusion, our blue, white, and black paper box packaging is a true masterpiece that blends striking aesthetics with functionality. With its full-color printing, mute film lamination, and the freedom to customize your branding and logo, it surpasses expectations on every level. So, let us take your packaging to new heights, as we offer you an unrivaled design service – all to ensure that your brand stands out and your products shine. Elevate your packaging game and make a statement with this premium paper box.

The lamination on the steroid vial labels and vial boxes

The importance of matte lamination in pharmaceutical anabolic steroids packaging lies in its ability to safeguard the integrity and quality of medicines. matte lamination, also known as blister films or strip films, is commonly used in the pharmaceutical industry to create individual compartments for each dosage unit, such as tablets or capsules. These films are typically made of PVC (Polyvinyl chloride), PVDC (Polyvinylidene chloride), or other advanced materials, providing several crucial benefits:

Protection from external factors: matte lamination act as a barrier, protecting steroids from moisture, oxygen, light, and other environmental factors that could degrade the drug’s potency or stability. By preventing exposure to these elements, the shelf life of the medicines can be significantly extended.

Dosage accuracy: The individual compartments created by matte lamination ensure accurate dosing of the steroids. This is particularly important for drugs with strict dosage requirements, as it minimizes the risk of dosage errors during production, distribution, and patient use.

Tamper-evident packaging: matte laminations are designed to be tamper-evident, meaning they show visible signs if someone attempts to manipulate or open the package. This feature provides an added layer of safety and helps consumers verify the product’s integrity before use.

Hygiene and contamination control: By enclosing each dosage unit separately, matte lamination reduces the risk of cross-contamination between different medicines. This is especially crucial for patients who need to take multiple medications simultaneously.

Compliance and convenience: The individualized packaging makes it easier for patients to adhere to their prescribed treatment plans. The packaging often includes labels with dosage instructions and other essential information, helping patients to take their medications correctly.

Stability and efficacy maintenance: Some drugs are sensitive to moisture or oxygen and may degrade rapidly if not properly protected. matte lamination provides an airtight and moisture-resistant environment, ensuring the drug’s stability and efficacy are maintained until the time of use.

Regulatory requirements: Pharmaceutical packaging must meet strict regulatory standards to ensure the safety and quality of steroids. matte lamination is commonly used in compliance with these regulations, ensuring that medicines are packaged appropriately for distribution and sale.

In summary, matte lamination plays a critical role in pharmaceutical anabolic steroids packaging by preserving the quality and efficacy of medications, enhancing patient safety, and meeting regulatory requirements. They provide an essential barrier against external factors, ensure accurate dosing, and contribute to the overall integrity of pharmaceutical products.

How to choose suitable 10ml vials for my steroid brand?

A 10ml vial of penicillin (also known as a “Westling vial”) is commonly used in the pharmaceutical industry for the packaging and administration of penicillin-based medications. The vial typically comes in various types and specifications to meet different medical needs and requirements. Here are some common types and details:

Type of Vial:

Standard 10ml Westling vial. This is the most basic type of 10ml penicillin vial commonly used for packaging various penicillin-based medications.

Type I Amber Glass Vial:

This vial is made from high-quality Type I amber glass, which provides excellent protection against light and helps to preserve the stability and potency of the medication.

Type II Clear Glass Vial:

This vial is made from Type II clear glass, which is suitable for medications that do not require protection from light exposure.

Rubber Stopper and Aluminum Seal:

The vial is typically closed with a rubber stopper to maintain an airtight seal, preventing any contamination or leakage. An aluminum seal crimps the rubber stopper onto the vial’s neck for added security.

Single-Dose Vials:

10ml penicillin vials are often designed for single-dose usage, ensuring accurate dosing and reducing the risk of contamination from multiple needle insertions.

Sterile and Pyrogen-Free:

Penicillin vials are manufactured under strict sterile conditions and are tested to be pyrogen-free to ensure the safety and efficacy of the medication.

Labeled and Serialized:

Each vial is usually labeled with essential information, including the medication name, strength, volume, batch number, and expiration date. Serialization helps with traceability and quality control.

Usage:

10ml penicillin vials are commonly used in hospitals, clinics, and healthcare facilities for various medical conditions, including bacterial infections that are susceptible to penicillin.

Storage:

The vials should be stored in a cool, dry place away from direct sunlight, as specified by the manufacturer, to maintain the medication’s stability and potency.

Disposal:

Proper disposal of used vials is essential to prevent contamination and environmental hazards. Healthcare facilities should follow proper guidelines for disposing of medical waste, including empty vials.

It is important to note that specific details of the 10ml penicillin vial can vary depending on the manufacturer and the specific medication being packaged. Healthcare professionals should always follow the manufacturer’s instructions and guidelines for handling and administering medications from these vials to ensure patient safety and medication efficacy.

Order Process

Payment

Logistics and Transportation

Reviews

There are no reviews yet.