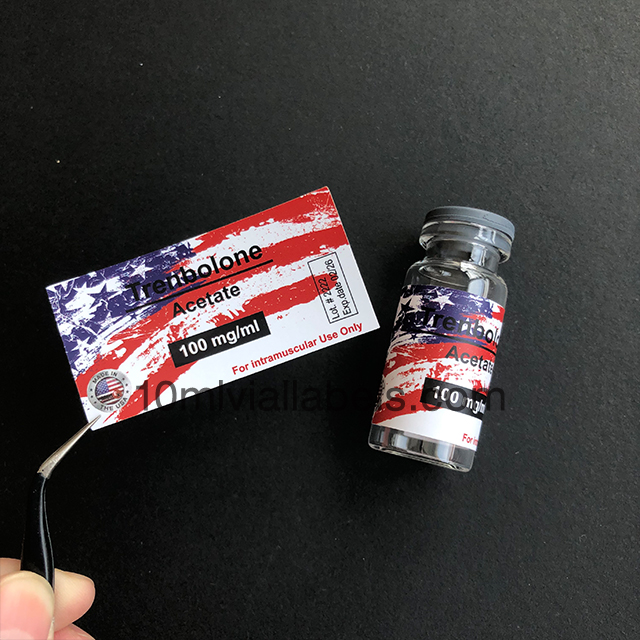

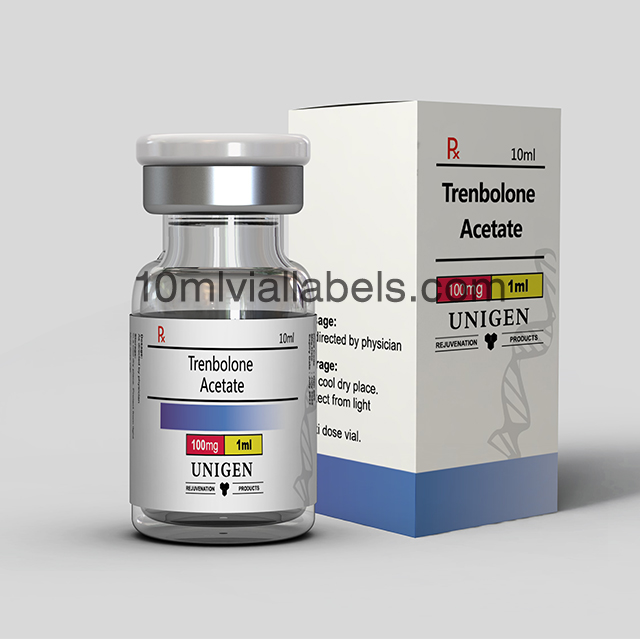

| Vial Label | Vial Box |

| Material: 80gsm coated paper sticker | Material: 250gsm white card paper stock |

| Size: 30mmx60mm or as your request | Size: 25mmx25mmx56mm or as the customer request |

| Design: US flag or customized | Design: US flag or customized |

| Lamination: glossy / matte | Lamination: glossy / matte |

| Injection Name: Trenbolone Acetate, Tren A, Trenbolone A | Injection Name: Trenbolone Acetate, Tren A, Trenbolone A |

| Dosage:100mg/ml | Dosage:100mg/ml |

| Application: steroid anabolic | Application: steroid anabolic |

Size & Shape Recommendation

No tears, no wasted material, no accidental white space — just make your unique vial label, perfectly printed. The die-cut shape created just for your own pharma business can create a distinctive look and visual effect for your end buyer.

NOVATIS can offer you different shape vial labels. If you compare your pharma business to a concert, the perfect die-cut shape is the rosin for the violin which can make your products with better performance.

About Lamination

Why do you need the lamination?

- Truer colors

By enclosing your printed materials in a completely see-through layer, lamination ensures that clients see the sharp, bright colors you intended. - Easier disinfection

In today’s world of increased hygiene practices, laminated products are useful because they can be easily disinfected. Simply wipe a laminated product with a disinfectant wipe, and it’s clean and ready to be used again. - Increased durability

Lamination is an essential tactic for making your printed products sturdier and longer-lasting. Gloss lamination in particular gives your products an almost indestructible quality, making them far less subject to water and difficult to damage. Fingerprints, smudges, and oil are easily wiped off. They’re also less likely to tear or fold. - Fewer replacement costs

Lamination’s protective qualities mean that your items are less likely to experience wear and tear, so you’ll need to replace them much less often. Over time, this can amount to significant savings; the small cost of adding lamination to your print order frequently pays off in the long run. - Additional luxury

Sensory experiences are a key influence when marketing and making sales. The beautiful look and pleasing feel of laminated products increase confidence in your company and make your products, and therefore your company, more desirable.

Types of lamination?

Whether you are new to printing and packaging or you have been in the printing field for a while, you might have noticed there are several lamination options.

Choosing lamination on the printed paper or printed sticker is helpful to protect the printed item from general wear, and tear, and basic waterproofing. Besides, it can also help improve the longevity of steroid labels and boxes. Lamination is simply sorted by: Glossy lamination, matte lamination, and Special lamination.

- Glossy lamination

The plastic film used in glossy lamination is smooth, which reflects a lot of light and makes the item shiny quality. Glossy lamination could be a popular choice in the packaging, and it is easy to see why. Content on the labels or the boxes, no matter writing or image, often appears crisper and sharper, whilst also having more contrast. Glossy lamination is also a durable choice as it prevents dirt, dust, and fingerprints with wipes ease.

- Matte lamination

Matte lamination is a common type of lamination that adds a smooth, clear matte finish to printed materials. Matte lamination provides a kind of feeling elegant and sophisticated finishing, which is why it is a common choice for many luxurious concept brands. Compare to glossy lamination, the matte one is more natural and dull, the color is closer to what is was. It can also provide a softer look as matte lamination can produce lower contrast on darker colors.

- Special lamination

Velvet texture lamination is a luxury matte lamination with a soft, almost peach fuzz-like texture. As it is often used on novel covers or some high-end cosmetic paper boxes, we will not go into details here. Customized logo lamination means putting your logo on the lamination. A holographic logo can be arranged in a line or random on the film, it can help the brand’s anti-counterfeiting. However, you can only choose glossy lamination as the basic layer for the custom one.

How to choose suitable lamination?

- Consider your product’s market

If your market is huge and it will be handled by many people during the selling process, consider a thicker glossy lamination that provides extreme protection. If you aim at luxury and elegant, matte could be a choice - Choose based on the colors preference

If you are looking for bright, exciting colors, such as for young and energetic people, then glossy lamination is probably the right choice for you. However, if you prefer more subtle colors, such as top-grade and sumptuous, then matte lamination is the way to go. - Imagine your intended emotional effect

If you want your brand to inspire ideas of luxury, you probably have an option for special lamination. It is a particularly good choice for steroid packaging, which contributes to your client’s first impression of you and your business.

FAQ

Q: Does your team help design?

A: Yes, NOVITAS has over 16 years of experience in pharmaceutical packaging design and production, especially in vial labels and vial boxes.

Q: How much do I need to pay for the design?

A: “0”, Because all of our designs are free. You can send us your ideal products for reference.

Q: What is the minimum quantity?

A: Usually, our MOQ is 100 pcs per name per design, but more quantity has a better price.

Q: Can we get some samples before ordering?

A: Of course, we will arrange a pre-printing sample for you, just to confirm every detail.

Q: Can I check all designs before bulk production?

A: Yes, we send all labels and boxes design in a clear jpg file for you to confirm. The bulk production will be arranged after your approval of the design and production details.

Q: Can I change the design after confirmation?

A: The design cannot be changed once you approved. If you really need to adjust after the confirmation, you need to pay for the cost which been raised by the production process.

Q: How long can I get my products?

A: Usually, for common finishing,

1000-20000pcs vial boxes and labels , production time is 5-7 working days ;

20001-100000pcs vial boxes and labels, production time is 10-15 working days;

If you need an urgent order, we can negotiate it. Besides, the finishing on the labels and boxes you need might length the lead time.

Q: How about shipping?

A:If you choose by express, it normally 5-7 days from our factory to your door;

If you choose by air, it normally 9-15 days from the factory to your door;

If you choose by sea, it normally 30-45 days from our factory to your door;

Usually, the shipment includes custom clearance and duty payment service, and it is door-to-door service.

Q: Can I receive the product without a problem?

A: You can receive the products safely if the shipping details are correct.

Q: Do you have any after-sale service?

A: Customized products are built to your specifications, so your order CANNOT be canceled, refunded, and/or credited for the purchase of another product after we have received your confirmation.

We DO NOT accept products for return unless items are defective, in which case they will be replaced, subject to availability, or refunded at your discretion.

Q: How to place the order with NOVITAS?

A: Please Send an inquiry to our email or send a message through WhatsApp, our sales will help you get your own brand vial labels and vial boxes.

Order Process

Payment

Logistics and Transportation

Reviews

There are no reviews yet.