A Comprehensive Guide:Choosing the Perfect Material for Vial Labels

Introduction

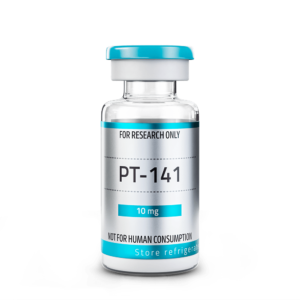

When it comes to vial labels, selecting a suitable material is crucial for both functional and aesthetic purposes. The right choice ensures your labels adhere properly, withstand environmental conditions, and effectively communicate essential information. In this article, we will delve into the factors to consider when choosing vial label materials, providing you with valuable insights to make informed decisions.

Factors to Consider for your vial labels

1. Adhesive Compatibility

To guarantee a secure bond between the label and the vial, it is vital to consider adhesive compatibility. Different materials require specific adhesives to ensure optimal adherence. For instance, plastic vials may necessitate a different adhesive than glass vials. By matching the material and adhesive compatibility, you can prevent label detachment issues.

2. Durability and Resistance

Vial labels often come into contact with various environments, such as extreme temperatures, moisture, chemicals, or friction. Choosing a durable material that can withstand these conditions is essential to maintain the label’s integrity and legibility. Materials like synthetic papers or polyester offer excellent durability and resistance, ensuring long-lasting labels.

3. Legibility and Print Quality

Clear and crisp printing on vial labels is crucial for readability and maintaining a professional appearance. Selecting a material that allows high-quality printing is vital to ensure essential information, such as product names, dosages, and instructions, remains easily readable. Smooth-coated paper or glossy finishes can enhance print quality, contributing to a visually appealing label.

Material Options

1. Vinyl

Vinyl labels are versatile and widely used in the pharmaceutical industry. They offer excellent durability, resistance to moisture, chemicals, and abrasion. Vinyl labels adhere well to various vial surfaces and maintain their integrity even in demanding environments.

2. Polypropylene

Polypropylene labels are known for their exceptional clarity, making them ideal for labels with small font sizes or intricate designs. They are resistant to water, oils, and most chemicals, ensuring the label remains intact and legible throughout the product’s lifecycle.

3. Paper-based Materials

Paper-based materials, such as coated papers or synthetic papers, are cost-effective options suitable for short-term applications. They offer good print quality and readability but may not withstand harsh environmental conditions as effectively as vinyl or polypropylene.

Conclusion

Choosing the suitable material for vial labels is a critical decision that impacts both the functionality and visual appeal of your products. By considering factors such as adhesive compatibility, durability, resistance, and print quality, you can select the perfect material that ensures long-lasting, legible labels. Whether you opt for vinyl, polypropylene, or paper-based materials, make sure they align with your product’s requirements and enhance your brand’s image.

Tags: vial labels, label materials, adhesive compatibility, durability, resistance, legibility, print quality, vinyl, polypropylene, paper-based materials, pharmaceutical industry

Leave a Reply

Want to join the discussion?Feel free to contribute!